INCONEL WASHER

INCONEL WASHER MANUFACTURER

The Apexia Metal Is Inconel Washer, Inconel Alloy Sealing Washer, Inconel Alloy Flat Washer. Inconel ASTM B166 Split Washer, Incoloy Grooved Washer Suppliers

Inconel Star Washer Exporter. Inconel ASTM B166 Mechanical Washer Distributor, Inconel Wire Spring, Inconel Flat Spring Manufacturer

Protection against sulfur-containing gases makes our Inconel flat washers. an attractive material for applications such as coal gasification units, burners. and channels for handling sulfuric corrosives. These Inconel washers have high strength over a wide temperature range. The limited carbon. in addition to the columbium setting in our Inconel sealing washers. allows welded fabricators to be used in destructive conditions. regularly without post-weld heat treatment. These Inconel split washers feature predominant pressure rupture clogging. that is often used in steam-age atomic reactors for funnels, separators, and welds.

The properties of our Inconel slot washers are useful for a variety of applications. including corrosive nitric or nitric/hydrofluoric arrangements. In air circulating through I Chronicles, Caustic Soda at 600 degrees F (316 degrees C). the U-torque samples from these Inconel machine washers did not break in 9400 h. Erosion rates for our Inconel Star washers in decreasing oxidizing and sulfurizing airs. Likewise, we are investors and suppliers of those Inconel Flat Spring Washers. transporting the entire planet. The mechanical properties of Inconel wire spring washers change. with the structure and temper of the article.

ASTM B166 Inconel Flat Washer, Inconel Spring Washer, Incoloy Spherical Washer. Inconel Perforated Washer, Incoloy Round Washer, Inconel Square Washer Manufacturer

INCONEL WASHER MANUFACTURER IN INDIA

Inconel Washer Specifications

Specifications: ASTM B166

Standard: DIN, ASTM, BS, and every international standard

Length: M02 to M33

Size: 3mm to 200mm

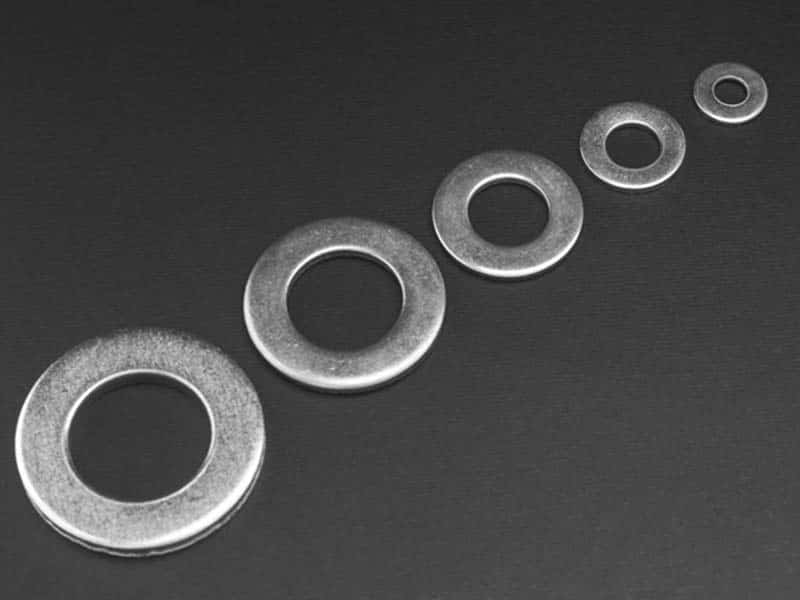

Type: Flat Washer, Washer, Sealing Washer, Split Washer, Slotted Washer, Machine Washer. Star Washer SPRINGS – Wire Spring and Flat Spring

Different grades of Inconel washing machine

Inconel 600 Washers

Inconel 601 Washers

Inconel 625 Washers

Inconel 718 Washers

Incoloy 800 / 800H / 800HT Washers

Incoloy 825 Washers

Incoloy 925 washers

Incoloy 330 / SS 330 / Ra 330 washers

Inconel 718 Washers

Producer of ASTM B637 718 Inconel Machine Washer, 718 Inconel Star Washer Exporter. Inconel UNS N07718 Wire Spring, Inconel WERKSTOFF NR. 2.4668 Flat spring manufacturer

Inconel Alloy 718 Flat Washer, Inconel 718 Washer, Inconel Alloy 718 Sealing Washer. Inconel ASTM B637 Split Washer, Alloy 718 Slotted Washer Suppliers

Inconel 718 flat washers are solidified by precipitation of optional stages. (eg, gamma prime and gamma double-prime) on the metal grid. Inconel 718 Lock Washers resist strong opposition to rust consumption. and clogging and are used for parts requiring high protection against deformation. and stress shear up to 1,300 degrees F (704 degrees C).

Inconel 718 Sealing Washers is used by a variety of companies including aviation. marine design, substance handling, pollution control hardware, and atomic reactors. Inconel 718 split washers are also used in gas turbines. spacecraft, rocket engines, pumps, etc. miniature shot – granulated. covered and cleaned whenever necessary.

The phenomenal strength and clogging of consumption of the Inconel 718 machine washers. are perceived by the oil industry and are currently widely used in this field. is the perfect heat treatment for these Inconel 718-star washers. where a combination of wear life. flexibility. and break life is required. The aging solidification reaction of Inconel 718 spring washers allows for unlimited hardening. and welding without solidification during heating and cooling.

Inconel 718 Washer Specifications

Specifications: ASTM B637

Standard: DIN, ASTM, BS, and every international standard

Length: M02 to M33

Size: 3mm to 200mm

Type: Flat Washer, Lock Washer, Sealing Washer, Split Washer, Slotted Washer, Machine Washer. Star Washer SPRINGS – Wire Spring and Flat Spring

INCONEL FLAT WASHERS

INCONEL PROPERTIES 600, 625 and 718

Inconel 600: Nickel-chromium combination with great opposition to oxidation at high temperatures. with great clogging under carburizing conditions and chlorides.

INCONEL WASHER SUPPLIER

Inconel 625 – Maybe an unattractive nickel-based blend. safe for consumption and oxidation. Its remarkable strength and robustness within the cryogenic. temperature range of 2000 ° F (1093 ° C). they are often used in a variety of scandalous conditions. from heat protectors to rare saltwater applications.

Inconel Washer Standard Grades

Inconel 600

The 600 combinations. UNS N06600 can be a nickel-chromium compound with great opposition to carburization. and oxidation up to 2000 ° F. The composite has been used for some time in the heat treatment industry. and Inconel 600 has valuable protection against dry gases of Cl2. and HCl at moderately elevated temperatures.

Inconel 601

Inconel 601, UNS N06601. is exceptionally impervious to oxidation at 2200 ° F significantly under serious hot cycling. The compound has a great heat resistance and maintains its flexibility after prolonged opening. The combination of Inconel 601 has great opposition. to hot consumption under oxidizing conditions.

Inconel 625

Inconel 625, UNS N06625, is the workhorse of the Inconel family and is possibly the best-known grade. It exhibits high resistance to spoiler popping and is impervious to oxidation at 1800 ° F (982 ° C).

Inconel 625 has fantastic protection against hot seawater, scrubber conditions, and reducing acids. and this mix stands up to a good variety of seriously destructive conditions. and is especially impervious to pitting and crevice erosion.

Inconel 686

The 686 combinations, UNS N06686, are destined for notable resistance to consumption. during a wide range of great conditions. The blend is used under the most severe conditions experienced in compounding. contamination control, maceration, and paper creation, and fresh and civil waste treatment.

INCONEL WASHER SUPPLIER IN INDIA

Inconel 686 Specifications: ASTM B 462, ASTM B 564 / ASME SB 564, ASTM B 574 / ASME B 574, DIN 17752, DIN 17753, DIN 17754

Inconel 718

Inconel 718, UNS N07718, is the best-known grade of the hardenable Inconel. This precipitation-solidified nickel-chromium compound has remarkable resistance. to erosion and high resistance to elevated temperatures.

The blend is approximately 2x stronger than Inconel 625. and has incredible thinner break resistance at temperatures up to 1300 ° F (700 ° C) and usable up to 1800 ° F (982 ° C). Inconel 718 is often used in gas turbines, rocket engines, shuttles. atomic reactors, siphons, and tools. For more in-depth data, download our Inconel 718

Inconel 600 Fasteners

• Inconel 601 fasteners

• Inconel 625 fasteneras

• Inconel 718 Fasteners

• Inconel 800-800H Fasteners

• Inconel 825 Fasteners

• Inconel 925 Fasteners

• Inconel X750 Fasteners

About

We are one of the leading manufacturers of optimum quality Pipes & Pipe Fittings. Their high tensile strength, seamless finish and resistance to corrosion, make these pipes highly demanded.

Register Office

Contact

(+91) 9167472806

apexiametal@gmail.com

export.apexia@gmail.com

Follow

Copyright 2021 © Apexia Metal – All Rights Reserved || Developed & Maintained by Adsense Networks